English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

- Boom Sprayer

- Air Blast Sprayer

- Lawn Mower

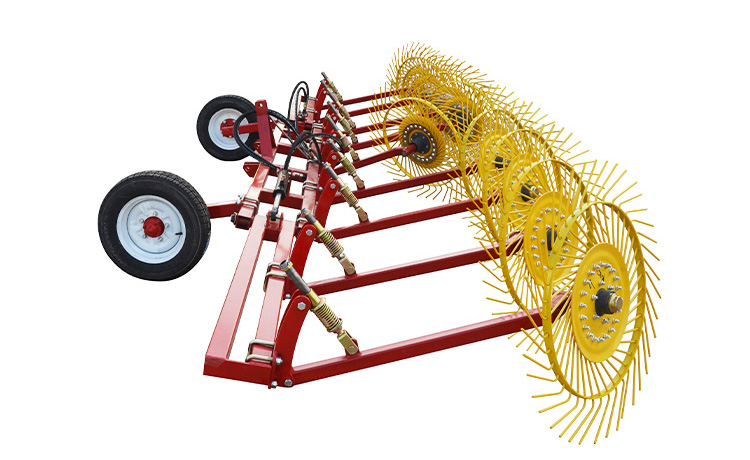

- Wheel Rake

- Land Leveler

- Fertilizer Spreader

- Manure Spreader

- Seeder Machine

- Agricultural Machinery Transmission Shaft

- Plow

- Automatic Roll Tube Sprayer

- Gear Pumps

- Hydraulic Valve

- Bundled Straw Net

- Tractor Flail Mower

- Seedling Killing Machine

- Rotary Rake

- Rake Sun

- Ridging Machine

- Rotary Tiller

Field Hay Rakes

Send Inquiry

Working Principle

The working principle of the field hay rakes is mainly based on the power transmission of the tractor. It achieves precise control of the materials through the structured movement of the roller and harrow components, and enables flexible adjustment of operation parameters to adapt to different field conditions and material states.

Work process

1. Pre-harvest drying: After the field hay rakes harvesting fresh grass, a wide-area drying method is adopted. The width of the spreading rollers is adjusted to the maximum, and the moving speed is slowed down. The fresh grass is evenly spread into a thin layer of 3-5 centimeters thick, using sunlight and wind to accelerate the evaporation of surface moisture. Usually, the first turning and spreading operation is carried out after drying for 2-4 hours.

2. Mid-term drying and spreading: When the moisture content on the surface of the hay drops to 30%-40%, the drying and spreading operation should be carried out. The moving speed should be reduced, and the moist materials from the lower layer should be turned to the surface to ensure uniform evaporation of moisture and avoid local mold growth. The frequency of drying and spreading can be adjusted according to the weather conditions.

3. Post-harvest gathering: When the dry grass reaches the standard moisture content, the mode is switched to gathering. The scattered dry grass is gathered into standard grass strips to prepare for the subsequent picking and baling operations. During the gathering process, the density of the grass strips should be controlled to avoid excessive density causing internal moisture to remain, and too loose a density will affect the baling efficiency.

The field hay rakes are designed to be towed by a tractor and can perform tasks such as spreading fresh hay, turning and raking dry hay, and gathering it. The rake's teeth are made of high-strength steel, which is durable and unlikely to break. It can be flexibly adjusted to change the angle and depth of operation, preventing soil from contaminating the hay. The operation is efficient and labor-saving, accelerating the evaporation of moisture from the hay, gathering it into standard bales, and being suitable for subsequent baling processes, as well as various materials such as wheat straw and pasture grass.