English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

- Boom Sprayer

- Air Blast Sprayer

- Lawn Mower

- Wheel Rake

- Land Leveler

- Fertilizer Spreader

- Manure Spreader

- Seeder Machine

- Agricultural Machinery Transmission Shaft

- Plow

- Automatic Roll Tube Sprayer

- Gear Pumps

- Hydraulic Valve

- Bundled Straw Net

- Tractor Flail Mower

- Seedling Killing Machine

- Rotary Rake

- Rake Sun

- Ridging Machine

- Rotary Tiller

Hay Rakes

Send Inquiry

These hay rakes can be installed on the three-point suspension device of a wheeled tractor. Its working components are finger-shaped discs with collection teeth. The machine sequentially transmits the working components to the next finger-shaped disc until a loose and ventilated grass belt is formed. Changing the angle of the finger-shaped discs can adjust the width of the grass belt.

The collection teeth are long spring steel teeth with good combing effect and strong shaping performance. They are arranged radially on the hub to eliminate the influence of wind and facilitate the passage of dust. The pressure exerted by the finger-shaped discs on the ground is controlled by tension springs. The ground pressure can be adjusted through the stretching adjustment plate according to the crops and ground conditions.

During transportation, the control lever can be turned to the rear of the tractor. These hay rakes have the simple structure, is easy to operate, has few faults, is easy to maintain, and has good power matching performance. It can both rake grass and perform drying operations (it can re-flatten the bundled grass strips). It can be used in conjunction with the lawn mower produced by our factory. It can integrate the three grass strips formed by the mowing width into a uniform strip, making it convenient for subsequent baling opera.

Operating Procedures:

When operating the dial wheel, it should rotate smoothly without any sticking phenomenon; the deviation of the axis line distance between adjacent dial wheels should not exceed 15mm; the deviation of the wheel ring distance between adjacent dial wheels should not exceed 15mm; all fasteners and connecting parts must be firmly and reliably installed; the lubrication injection points between each component must be checked and replenished in a timely manner; when the width of the hay rakes exceed that of the tractor, reflective signs should be installed; when performing complex repairs and adjustments of the hay rake, the tractor should be turned off or disconnected from the linkage before proceeding.

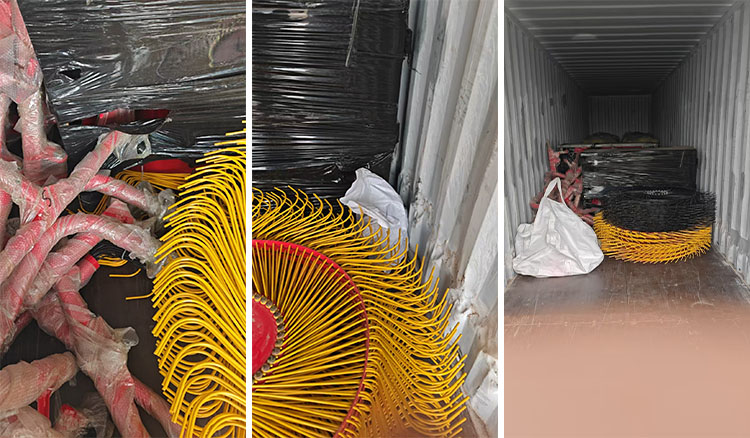

Packaging