English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

- Boom Sprayer

- Air Blast Sprayer

- Lawn Mower

- Wheel Rake

- Land Leveler

- Fertilizer Spreader

- Manure Spreader

- Seeder Machine

- Agricultural Machinery Transmission Shaft

- Plow

- Automatic Roll Tube Sprayer

- Gear Pumps

- Hydraulic Valve

- Bundled Straw Net

- Tractor Flail Mower

- Seedling Killing Machine

- Rotary Rake

- Rake Sun

- Ridging Machine

- Rotary Tiller

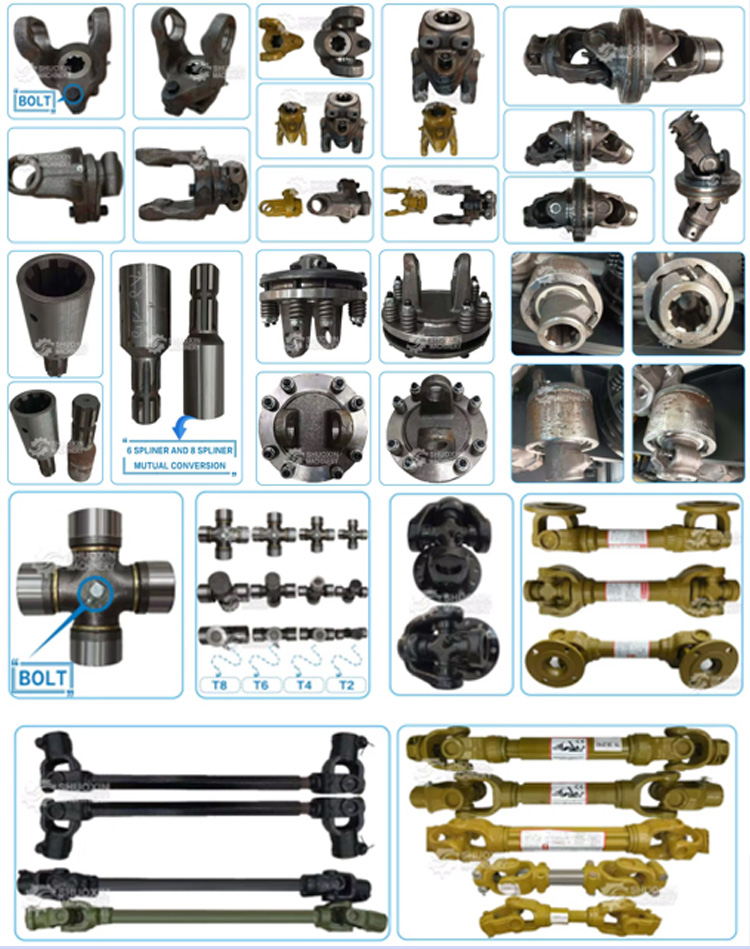

Tractor Cardan Shafts

Send Inquiry

The tractor cardan shafts of the tractor in agricultural machinery is the core power transmission component of the agricultural machinery transmission system. It adopts a cross-axis structure and is designed with connected telescopic tubes, as well as angular compensation capabilities, to ensure stable transmission even when the axis line changes due to terrain undulations during agricultural operations.It efficiently transmits the engine power to agricultural machinery tools such as tillers and harvesters.

Why is a universal drive shaft needed?

The tractor cardan shafts are composed of a universal joint and multiple connecting shafts. The universal joint is a rotational connection device that enables the connecting shafts to rotate in any direction. Each connecting shaft has a certain length. Some telescopic drive shafts can extend and contract as the distance between the wheels and the engine changes during vehicle travel, thereby reducing friction and vibration on the drive shaft.

Selection and Maintenance Key Points

Selection Principles:

Torque Matching: Select the cross shaft specification based on horsepower (e.g.,Plum tube for over 200 horsepower, triangular tube for under 100 horsepower).

Angle Limitation: The working angle of the standard model is ≤ 25°. For angles exceeding this limit, a large-angle transmission shaft needs to be selected.

Keyway Size: Domestic agricultural machinery commonly uses large 8-key (matching high horsepower) and small 8-key (for low horsepower), and it must be consistent with the interface of the agricultural machinery.

Maintenance Points:

Lubrication and Maintenance:Regularly add lubricating grease to the cross bearings and telescopic tubes to prevent metal wear caused by high temperatures.

Troubleshooting:

Cross Shaft Breakage:Often due to overloading or insufficient lubrication, replace the high-strength bearings and control the torque.

Telescopic Tube Deformation:Check if the working angle exceeds the limit. If necessary, install an intermediate support.

Life Extension:Avoid long-term full-load operation and regularly check the wear of the keyway.

Industry trends of the tractor cardan shafts

The ball cage type universal joint gradually replaces the traditional cross shaft, improving the transmission stability and lifespan.

Integrated overload protection devices (such as shear pins, friction clutches) are used to prevent damage to the transmission system.