English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

- Boom Sprayer

- Air Blast Sprayer

- Lawn Mower

- Wheel Rake

- Land Leveler

- Fertilizer Spreader

- Manure Spreader

- Seeder Machine

- Agricultural Machinery Transmission Shaft

- Plow

- Automatic Roll Tube Sprayer

- Gear Pumps

- Hydraulic Valve

- Bundled Straw Net

- Tractor Flail Mower

- Seedling Killing Machine

- Rotary Rake

- Rake Sun

- Ridging Machine

- Rotary Tiller

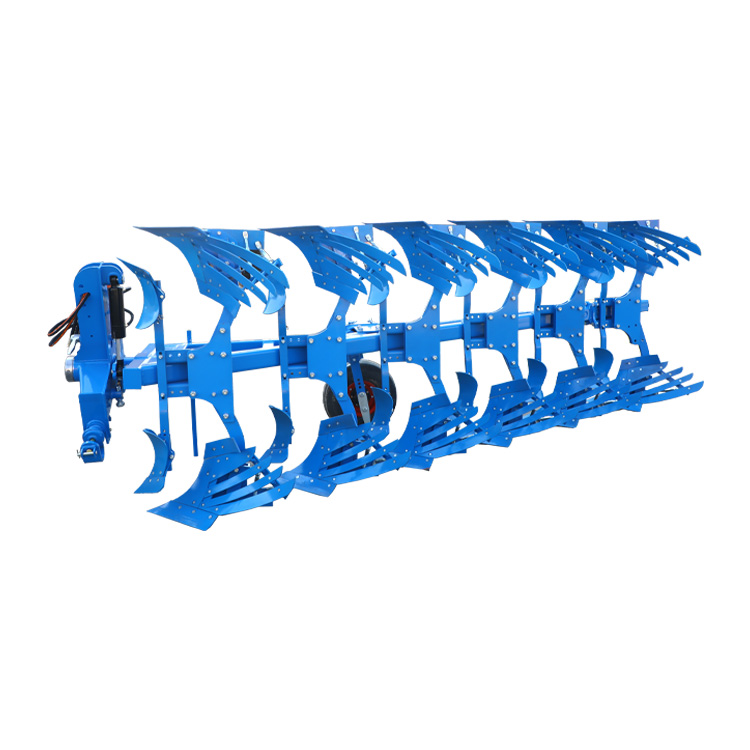

Reversible Flip Plough

Send Inquiry

The reversible flip plough is composed of six core modules: the suspension frame, the reversing cylinder, the check valve mechanism, the ground wheel mechanism, the plow frame, and the plow body. The plow frame is driven to vertically flip forward and backward by the extension and retraction of the piston rod of the cylinder. The ground wheel mechanism adopts screw adjustment technology to integrate the control of plowing depth and transportation functions.

Performance advantage

Efficient work ability

The bidirectional reversing function can increase the farming speed, enhance fuel efficiency, and the working width can reach 120-250 centimeters, which is 40% faster than that of traditional plows.

Environmental adaptability

The reversible flip plough is hung behind the tractor and starts working as soon as the tractor is started. It is operationally flexible and stable, and suitable for many terrains.

Economic indicators

The body and components are made of durable materials, which reduces maintenance costs by 60%, lowers the failure rate, extends the mechanical service life, and also improves the fertilizer utilization rate, thereby reducing the total input cost.

Application scenarios and selection suggestions

Power matching

Devices of different specifications should be matched with corresponding tractors. For example, 1LF-340 is suitable for tractors with around 100 horsepower, while 1LF-550 is suitable for tractors with over 200 horsepower.

Terrain Adaptation

In plain areas, it is recommended to choose models with a standard width of 140 centimeters. For areas with uneven terrain, it is suggested to use equipment with adjustable width design.

Shuoxin® not only produces reversible flip plough but also various agricultural machinery products. It also offers customization services. Some trademarks can be printed on the products through methods such as embossing, printing, embossing, coating or stickers. We provide different warranty periods for different products. For detailed information, please contact us.