English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

- Boom Sprayer

- Air Blast Sprayer

- Lawn Mower

- Wheel Rake

- Land Leveler

- Fertilizer Spreader

- Manure Spreader

- Seeder Machine

- Agricultural Machinery Transmission Shaft

- Plow

- Automatic Roll Tube Sprayer

- Gear Pumps

- Hydraulic Valve

- Bundled Straw Net

- Tractor Flail Mower

- Seedling Killing Machine

- Rotary Rake

- Rake Sun

- Ridging Machine

- Rotary Tiller

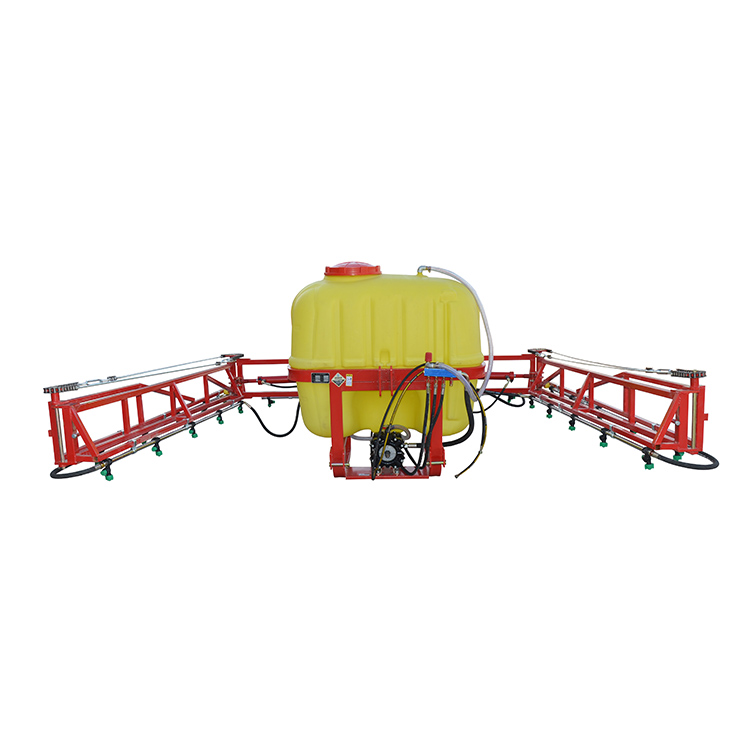

3 Point Boom Sprayers

Send Inquiry

Shuoxin 3 point boom sprayers are important agricultural machinery in modern agricultural applications, which can help farmers accurately and efficiently apply herbicides, pesticides and fertilizers to crops. The sprayer is composed of an arm and a nozzle, which mainly distributes the liquid evenly over a large area. Improve spraying accuracy, reduce waste, increase crop yield, and promote healthy crop growth

Analysis of working principle and core components of 3 point boom sprayers

1.boom structure

The heart of the boom sprayer lies in its flexible boom structure. The structure usually consists of long metal arms, the length of which can be adjusted according to the specific model and actual operating requirements.

2.The nozzle and its arrangement

Another key component of the sprayer is the nozzle that is evenly distributed along the boom. These nozzles are carefully designed and arranged to ensure that the liquid can be evenly and efficiently sprayed onto the crop. Different nozzle types are optimized for specific crops and application scenarios, providing more precise and efficient spraying.

3. Fuel tank capacity

The tank of the sprayer is where the liquid to be sprayed is stored. Tank capacities typically range from a few gallons to hundreds of gallons, and larger models are able to hold more liquid, which reduces the hassle of frequent refueling and improves operational efficiency.

4.Dynamic mechanism and movement

3 point boom sprayers are usually hydraulically driven, which makes the sprayer work more stable and accurate. Compared to other sprayers that are manually operated or attached to a tractor, hydraulically powered sprayers offer significant advantages in both efficiency and accuracy.

5. Decentralization process and efficiency

During the spray process, farmers can control the spray pattern and titer by adjusting the nozzle spacing and boom height. This precise control enables the sprayer to achieve uniform cross-field coverage while reducing spray drift and waste.

The features of 3 point boom sprayers

Improve crop health and yield

3 point boom sprayers are essential to improve crop health and yield by ensuring even and precise application of fertilizers and pesticides. This targeted approach minimizes chemical waste, improves crop absorption and makes plants healthier, while also increasing productivity. By optimizing spray patterns, farmers can effectively meet the needs of specific crops, ultimately achieving higher quality and more abundant harvests.

Targeted nutrient delivery: Farmers can apply fertilizer directly to crops, ensuring they get the nutrients they need to grow.

Improved pest control: Effective pesticide distribution helps reduce pests and diseases, leading to healthier crops and higher yields.

Consistent coverage: The product distributes the liquid evenly, eliminating the risk that under application or over application could damage the crop.

Improve efficiency and reduce labor costs

The use of boom sprayers has greatly improved the efficiency of modern agricultural production. Their ability to cover large areas quickly reduces the time and labor required for crop handling. This mechanization allows farmers to allocate resources more efficiently, reduce operating costs, and increase overall agricultural productivity.

Shortened application time: Fast coverage of large areas, arm-type sprayers significantly reduce the time required for crop spraying.

Labor and cost efficiency: Manual labor requirements are reduced, and boom sprayers reduce overall application costs and save resources.

Environmental protection measures

With accurate application rates, the 3 point boom sprayers reduces chemical runoff and can minimize the impact on the surrounding ecosystem. By harnessing advanced technologies, farmers can adopt sustainable practices that preserve biodiversity while maintaining effective pest and nutrient management, creating a healthier environment for future generations.

Control of chemical use: This product enables precise control of chemical applications and reduces environmental impact.

Reduced soil compaction: Minimizing soil disturbance, the product helps keep the soil healthy.

Water conservation: By minimizing water waste, 3 point boom sprayers contribute to sustainable agricultural practices.

Adjust boom height and nozzle position

Achieve the ideal boom height: Keeping the boom at the optimal height ensures even spray distribution, which is the key to effective coverage.

Proper nozzle spacing: Adjusting the nozzle spacing according to crop type and field size allows for customized spraying solutions.

Topographic effects on boom position: Adjustments may need to be made based on site topography to maintain an even spray pattern.

Regular maintenance and cleaning

Check for wear and clogging: Check nozzles, hoses, and pumps regularly for wear to maintain consistent injection patterns and avoid clogging.

Cleaning techniques: Thoroughly clean the rod and nozzle after each use to prevent residue buildup that can lead to clogging or uneven spraying.

Lubrication and component replacement: Keep moving parts well lubricated, replace worn parts, and extend the service life of the boom sprayer.

Safety precautions and environmental precautions

Wear protective gear: Operators should use protective gear such as gloves and masks when handling chemicals and handling sprayers.

Manage spray drift: Adjust nozzle Settings and spray pressure to minimize drift, especially in windy conditions.

Minimize environmental impact: Use recommended amounts of chemicals and dispose of any residues responsibly to protect nearby ecosystems.

If you'd like to learn more about how 3 point boom sprayers work, their important role in crop health, and key operational considerations, you can contact us at lucky@shuoxin-machinery.com.