English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

- Boom Sprayer

- Air Blast Sprayer

- Lawn Mower

- Wheel Rake

- Land Leveler

- Fertilizer Spreader

- Manure Spreader

- Seeder Machine

- Agricultural Machinery Transmission Shaft

- Plow

- Automatic Roll Tube Sprayer

- Gear Pumps

- Hydraulic Valve

- Bundled Straw Net

- Tractor Flail Mower

- Seedling Killing Machine

- Rotary Rake

- Rake Sun

- Ridging Machine

- Rotary Tiller

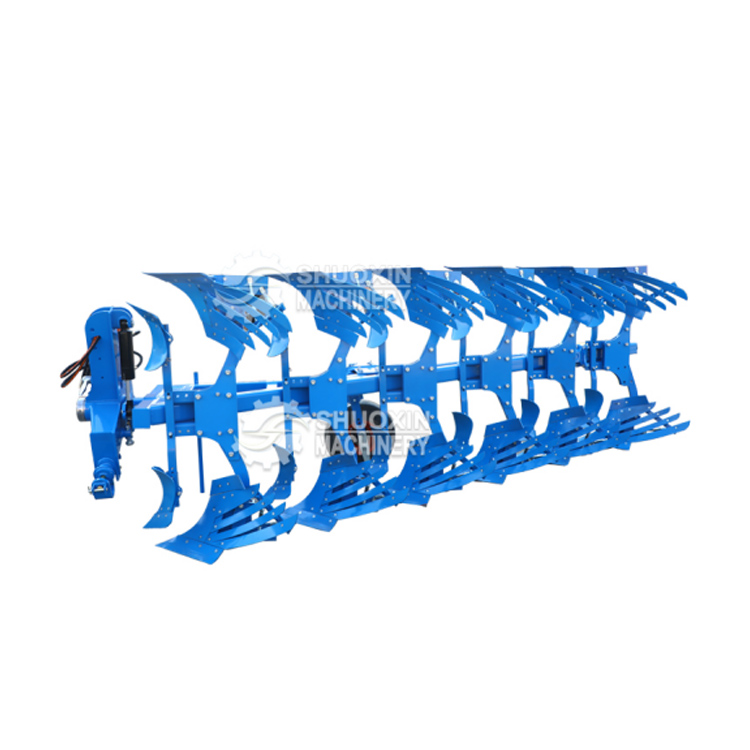

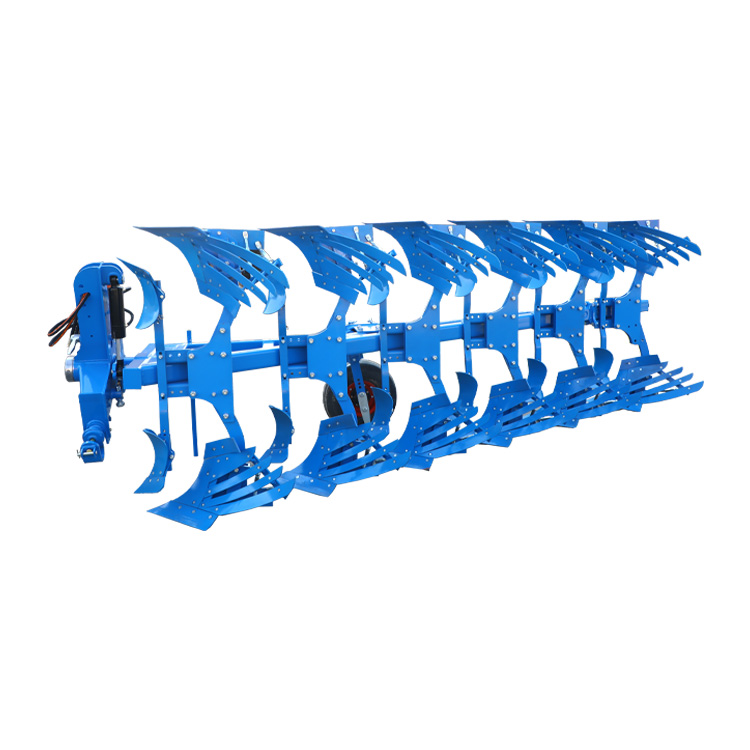

Reversible Flip Ploughs

Send Inquiry

The core of the reversible flip ploughs lie in its hydraulic flipping mechanism, which consists of components such as the flipping cylinder, suspension frame, plow frame, and flipping axis. During operation, when the tractor reaches the edge of the field and needs to make a turn, the driver operates the hydraulic control system of the tractor to make the plow frame rotate around the flipping axis. When the plow frame rotates to a state close to being perpendicular to the ground, the hydraulic system will automatically switch the oil flow direction, causing the piston rod of the cylinder to start extending. As the piston rod extends, the plow frame continues to rotate until the other set of plow bodies that were originally in a non-working position rotates to the working position. At this point, the plow frame is again parallel to the ground, completing one flip.

A practical farming tool that makes plowing a simple and easy task

No need to turn back and forth when plowing, saving time

With the traditional plow, you have to repeatedly turn around, which is time-consuming and also presses down the edges of the field. These reversible flip ploughs can be flipped 180 degrees. After plowing one section, it can simply turn around to return to the original position. It can plow any area neatly, doubling the efficiency.

It can be ploughed either on soft or hard ground

Whether it's a wet paddy field or a dry and hard compacted land, the curved surface of the plough body and the adjustable plough angle design of the plough can handle it easily. The plough tip is made of thickened manganese steel, and it is not likely to crack when hitting a stone. The soil turned out is fine and uniform, and the effect is much better than that of ordinary ploughs.

The operation is simple, even beginners can master it quickly

Hydraulic control for flipping, you can adjust the direction while sitting on the tractor. There's no need to get off and move the levers like in the old-fashioned plows. The reversible flip ploughs have limit wheels, and the depth of soil turning can be precisely adjusted. Deep plowing and shallow cultivation can all be done with one machine.

Energy-saving and labor-saving, it becomes more cost-effective in the long run

The two-way operation reduces empty travel distances, and the same area can save 20% of fuel. The structure is simple, the parts are sturdy and durable. Just wipe the dirt and tighten the screws daily. If the accessories are broken, replace them directly with standard parts without waiting for the manufacturer to deliver.

Suitable scenarios

● Large-scale flat farmland for timely harvest

● Straw returning to the soil requires deep burial and covering

● Alternating operations on sandy and clayey soils

● Cooperatives/ grain farmers with large-scale operations