English

English  Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

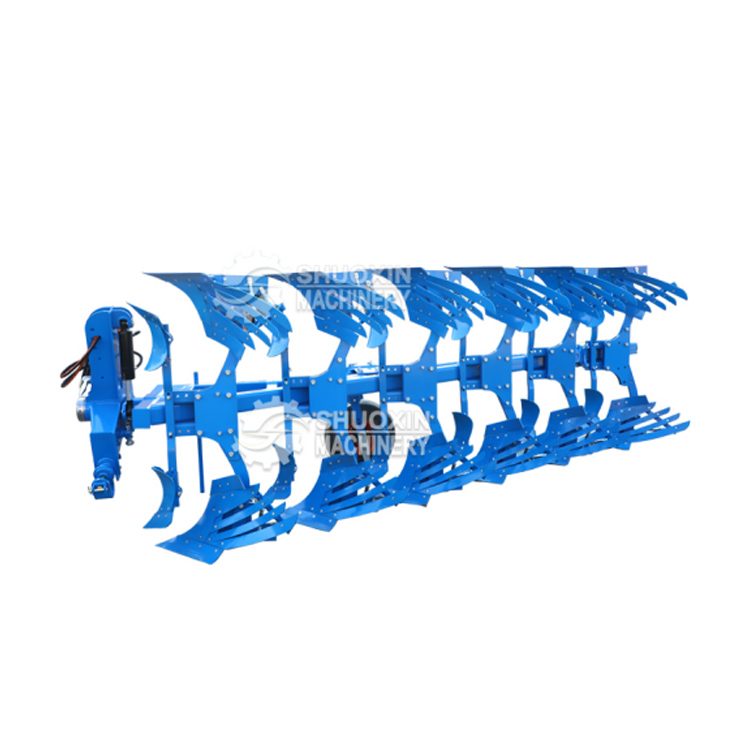

How to use Hydraulic Flip Plows?

2025-04-21

Hydraulic Flip Plows have the advantages of less empty travel at the end of the field during operation, no need to divide or combine the soil, and can shuttle back and forth along the furrow without furrows or ridges, and turn the soil uniformly. In recent years, it has been popular in the market and gradually replaced traditional traction plows and suspension plows. Today, let's talk about the correct use and adjustment of hydraulic flip plows.

1. Preparation

The first thing we need to do is the preparation work before plowing.

(1) Check the integrity of the machine, whether there are any damaged or missing parts, whether the bolts are loose, and ensure that the machine is intact and the bolts are tightened.

(2) Adjust the configuration of the first plow of the flip plow. When a wheeled tractor is plowing, generally one wheel should go through the furrow. The inner side of the tire that goes through the furrow generally maintains a gap of 1-2 cm with the furrow wall. When the first plow is installed, its lateral position should be placed so that the end of the plow is placed on the furrow wall line, so that the cutting width of the first plow is exactly equal to the design width of the single-plow body. Otherwise, when the Hydraulic Flip Plows shuttles back and forth, it will leave furrows or ridges between each working width.

(3) Check and adjust the wheelbase. Check the inner side spacing H of the tractor's rear wheel and the distance h from the first plow side plate of the equipped flip plow to the center of the rotating shaft. It is required to meet H/2=h+b, where b is the single-plow width. If this condition cannot be met, the flip plow must be adjusted. If the flip plow cannot be adjusted, the requirement can be met by adjusting the tractor wheelbase. When adjusting the wheelbase, adjust the rear wheel base first, and then adjust the front wheel base according to the rear wheel base.

(4) Check tire pressure. When plowing, the tire pressure should be 80-110KPa. Please refer to the manual for details.

(5) Check whether the tractor has enough hydraulic oil and whether the hydraulic quick connector is intact. When connecting the hydraulic oil pipe of the flip plow, connect it according to the oil pipe mark on the flip plow.

2. Hooking the hydraulic flip plow

After the inspection, we will hook up the Hydraulic Flip Plows. The wheeled tractor and the Hydraulic Flip Plows are hooked up with three-point suspension. Before hooking up, we need to adjust the left and right pull rods to ensure the level of the left and right pull rods. The specific adjustment method is as follows: park the tractor on a flat road, operate the hydraulic lifting handle to drop the pull rod, and check whether the center of the left and right pull rod connection ball head is consistent with the ground height. If the left and right heights are inconsistent, you can adjust the length of the left and right lifting rods to make them consistent. After the lower tie rod is leveled, the hydraulic flip plow is connected. The ball heads of the left and right lower tie rods are connected to the left and right lower suspension points of the plow respectively, and the pins are used to lock the anti-dropping. After the lower tie rod is connected, the upper tie rod of the tractor is connected, and the upper tie rod is connected to the upper suspension point of the hydraulic flip plow with a pin shaft and locked with a pin to prevent it from falling off. After the three-point suspension is connected, the hydraulic handle is operated to raise the hydraulic flip plow, and the left and right limit rods are adjusted so that the plow is in the middle of the two wheels, and the hydraulic flip plow can only shake slightly left and right.

3. Adjust the plow level

When the tractor is plowing, we adjust the horizontal level of the plow frame of the hydraulic flip plow to ensure that the plow column is perpendicular to the ground during plowing. Since the wheeled tractor usually walks on one side of the plow furrow during plowing, the tractor has a certain inclination angle, which will cause the plow frame to be horizontal, that is, the plow column is not perpendicular to the ground. Adjust the plow frame flip limit screw, and the plow column can be perpendicular to the ground after the plow enters the soil through the length of the limit screw. The lengths of the left and right flip limit screws need to be adjusted to ensure that the Hydraulic Flip Plows can maintain a vertical state with the ground during the reciprocating tillage stroke.

After adjusting the horizontal level, we also need to adjust the longitudinal level of the plow frame. If the longitudinal level of the plow frame is not horizontal, the front and rear plowshares will have inconsistent ploughing depths and longitudinal instability during flip plowing. When adjusting the longitudinal level of the plow frame, the main thing is to adjust the length of the upper pull rod. During plowing, observe whether the front and rear plow frames are level. When the plow frame is low in front and high in the back, the first plowshare of the flip plow will be too deep and the rear plowshare will be too shallow. Some will have a phenomenon of too deep plowing and cannot be pulled. At this time, the problem can be solved by lengthening the upper pull rod; if the plow frame is high in front and low in the back, the first plowshare will be too shallow and the rear plowshare will be too deep, and the plow will be difficult to enter the soil. At this time, we can solve it by shortening the upper pull rod.